For Chinese factories, particularly small to medium sized operators, this has been a very difficult time.

Many have struggled with the loss of orders, cash flow shortages, and being straddled with ongoing operation and inventory costs that have led to the government announcing a series of relief measures early on.

While preventing and controlling the COVID-19 outbreak has been the priority, enterprises all over the country have begun the process to production, and media reports have lead many to believe that China is now “open”. However, the reality is that the process of reopening has faced mixed results, with a recent by the Ministry of industry and information of the People’s Republic of China[1] showing that the work resumption rate of small and medium-sized enterprises was only 30%.

For those fortunate enough to be in a position to reopen, the challenges to do so have kept many closed or running far below capacity.

To better understand those challenges, we recently reached out to a small number of factory managers and migrant workers to better understand the challenges faced, and have come to broadly recognize the barriers below as five largest.

Challenge #1: Complexity of Reopening Process

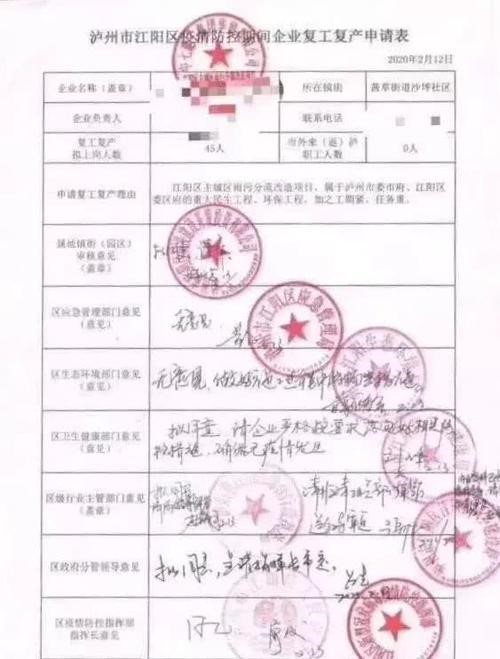

Currently, if a factory wants to reopen more than 20 files must be fill in. The files include 15 different forms, 2 commitment letters, 1 resumption of work plan, 1 proposal of canteen protection and 1 proposal of dormitory building[2].

Some of forms also need chops from local street community, which can be difficult for factory given many local street communities assume responsibility for the approvals that they have confirmed.

“local street community is extremely careful about the chopping process, it is only understandable, but do make the situation more complex”, a factory manager mentioned.

Challenge #2: Mandatory Quarantining and Shortage of anti-epidemic materials

To prevent future spreads of the epidemic, a series of policies were adopted. The most burdensome of which is that all migrant employees are required to quarantine for 14 days prior to returning to work. A process which must be done offsite, and as the costs of the quarantine are born by the worker themselves, many are reluctant to return

Additionally, to further reduce the risk of future outbreaks, enterprises must ensure that enough anti-epidemic materials for employees are in place, such as masks, hand sanitizer, disinfecting alcohol, etc. prior to reopening. A challenge given the shortage, and rising costs, of these items

“If we have one worker has been confirmed positive for COVID-19, not only this worker has been considered as suffered work-related injury, the factory has to pay for medical expenses, also the entire factory has to be quarantined for 14 days”, a factory manager mentioned, he also shared that “while the quarantine, the factory still need to pay workers’ salary and social insurance”.

Challenge #3 Willing Employees unable to leave hometowns/ return to factory:

Migrant employees-based enterprises are facing the problem of insufficient workers in place, many provinces are taking actions to the migrant population, either put them in quarantine or refuse the migrant employees who is without local ID to enter.

Compounding this challenge, is the fact that county-city train, buses and other means of transport are still suspended in many areas of China.

Challenge #4: Employees unwilling to return

In addition to the logistical challenges employees face, there are a number of other challenges back home that are preventing many from returning even though they face financial pressure to do so.

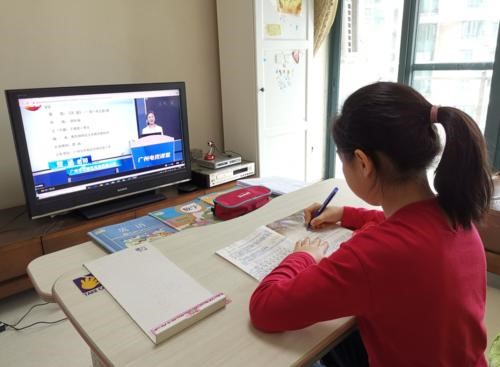

First and foremost, through our conversations with migrant workers, we have come to understand one of the main reasons they have decided to stay at home is due to the delay in school openings.

“Without going to school is extremely hard for my kids, because online study is not as convenient as studying at school, I have to help them to set up the internet and deal with technical issues that might happen. Besides that, I need to study with my kids and listen the lecture together, in case they cannot understand the contents”, a mother shared with us.

Separately, there are still a number of migrants who believe that staying in their home villages is safer. As on worker recently shared with us:

“I really feel safe to stay at home, because there is no mobile population in our village, I will go to big coast cities, but I want to see what would happen in the future”, a worker shared.

Challenge #5: Ongoing Uncertainty

Finally, with the spread of COVID impacting the global markets for goods, factory managers are faced with the challenge of navigating the risks of material shortages, logistics disruptions, and lose of orders due to “force major” clauses.

This uncertainly will most certainly make labor decisions more difficult over time as well, with the result being a reduction in migrant laborers who are willing to move for the promise of well paying, stable, manufacturing jobs.

Conclusion:

While the virus presenting one of the greatest challenges China, and the world has faced in a generation, the economy cannot stay idle. Resuming manufacturing is another high priority, and while we have detailed a number of the challenges we have seen, and continue see, above governments and enterprises have taken many positive measures to deal with the them.

In Hangzhou, authorities organized special trains for migrant workers, rented buses, and even organized flight to pick up the workers from other provinces to work. Many enterprises also set up a special response team to deal with the outbreak, detailed planning responsibilities to ensure the health and safety of employees.

Progress is being made, and while the country looks to open up, it is important to remember that as the processes for reopening grow easier, and the investments in health and safety of migrant workers are made, it will likely require a few more months before China’s factories are able to achieve full employment and production.